Comparing Welded Wire Mesh Panels and Woven Wire Mesh: Pros and Cons

Welded wire mesh panels and woven wire mesh are two common types of mesh materials widely used in various applications, including construction, industrial, and agricultural sectors. Both options offer distinct advantages and disadvantages, making them suitable for different purposes. This article compares welded wire mesh panels and woven wire mesh, with a focus on stainless steel wire mesh, to help readers understand the strengths and limitations of each type and make informed decisions based on their specific needs.

Introduction:

Wire mesh plays a crucial role in a myriad of applications, ranging from reinforcing concrete structures and securing fences to filtration and sieving processes. Welded wire mesh panels and woven wire mesh are two prevalent forms of wire mesh, each with unique characteristics. Stainless steel wire mesh, in particular, is often used due to its corrosion resistance and mechanical properties. This article aims to provide a comprehensive comparison of the pros and cons of welded wire mesh panels and woven wire mesh, focusing on the application of stainless steel wire mesh.

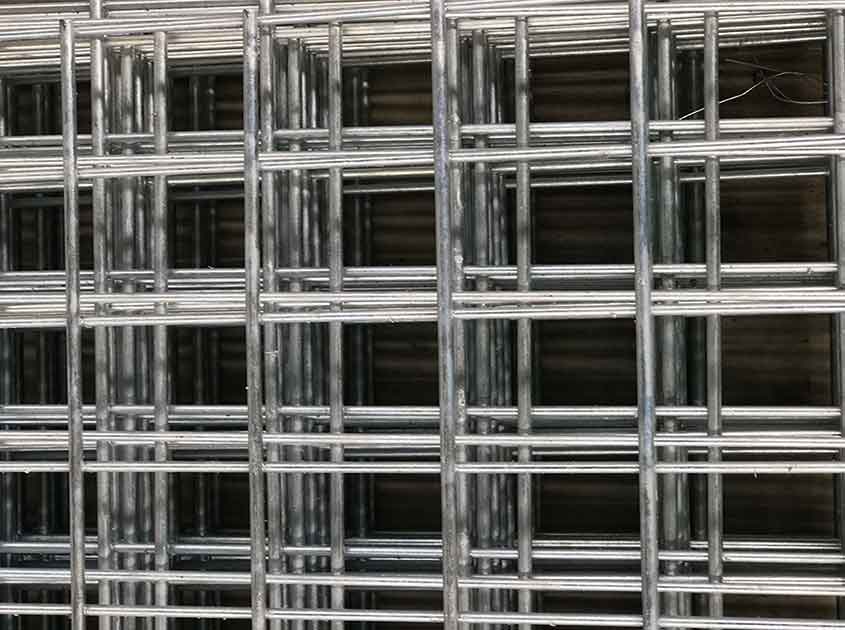

Welded Wire Mesh Panels:

Pros:

Structural Integrity: Welded wire mesh panels offer superior structural integrity due to the fusion of wires at their intersections. This feature provides excellent strength and load-bearing capacity, making them ideal for reinforcing concrete structures and other heavy-duty applications.

Uniformity: The welding process ensures consistent mesh openings and wire spacing throughout the panel, leading to precise and uniform reinforcement in concrete and reliable filtration capabilities.

Easy Installation: The rigid panels are easy to handle and install, reducing labor time and ensuring a hassle-free setup in construction and industrial projects.

Cons:

Reduced Flexibility: Welded wire mesh panels are less flexible than woven wire mesh, limiting their adaptation to curved surfaces or irregular shapes.

Prone to Cutting: The welded intersections may be susceptible to cutting or damage if exposed to excessive stress or impact.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China